Genuine Parts

QUALITY

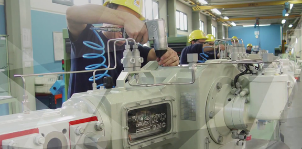

Aspro spare parts are manufactured In Argentina and its plant has a large production capacity.

SAFETY

ISO 9001: 2015 certified, guaranteeing the highest safety standards in the production of each original spare part.

EXPERIENCE

Aspro has been in the CNG market for more than 3 decades, with more than 5,400 pieces of equipment sold around the world, making it the most experienced brand to offer quality spare parts.

SERVICE & MAINTENANCE

In order to satisfy the needs of each client, Aspro offers specialized technical assistance, original spare parts and preventive maintenance programs through its international after-sales service network present in 38 countries. Each representative is trained on the latest technologies and has a large stock of original spare parts available to customers in their region to offer quick assistance, ensuring that Aspro compression systems perform at their maximum potential. Customer service is one of the key values for growing in the international market, which is why we have specialized personnel working together with each client that owns Aspro piece of equipment. By working to provide effective solutions, ensuring that your business is profitable, reliable, and safe.

Preventive Maintenance

To guarantee the compression systems’ performance and continuously maintain its highest performance, Aspro specially designed the preventive maintenance programs that suit each customer needs. Respecting maintenance protocols defined by the manufacturer and getting an official representative for repairs is the most effective way to reduce risk, improve reliability and assure the best profitability of the station.

BENEFITS OF A PREVENTIVE MAINTENANCE PLAN:

- Increases the productivity

- Minimizes unplanned stops

- Eliminates unnecessary maintenance and inefficient tasks

- Focus resources where they are really needed

- Meeting safety and environmental regulations

- Schedule investments and enhance the compressor’s lifespan

Remote Monitoring

Aspro provides monitoring systems that reduce field visits and keep the operation controlled remotely. They include real-time telemetry of the compressor unit and motor with digital indicators and operating alarms. The system sends instant messages and alarms in real time, while also allowing the user to collect and access historical data for analysis.