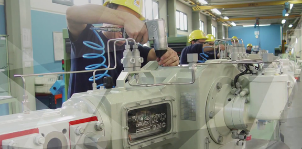

COMPRESSOR IODM 70

Aspro IODM 70 compressors, due to their simple functioning and high performance, are an ideal solution adaptable to high capacity refueling stations demands, guaranteeing a quick, efficient and safe CNG refilling.

- Inlet pressure: 0,02 to 60 bar (0,29 to 870 PSI)

- Flow: 120 to 1.050 Nm³/h (71 to 618 SCF/m)

- Horizontal reciprocating of 2 / 3 / 4 / 5 stages

- Direct coupling

- Electric motor or gas driven engine

- Power: 55 / 132 kW (75 / 175 HP)

- Air cooled

- Last compression stage condensers

COMPRESSOR IODM 70

Aspro IODM 70 compressors, due to their simple functioning and high performance, are an ideal solution adaptable to high capacity refueling stations demands, guaranteeing a quick, efficient and safe CNG refilling.

- Inlet pressure: 0,02 to 60 bar (0,29 to 870 PSI)

- Flow: 120 to 1.050 Nm³/h (71 to 618 SCF/m)

- Horizontal reciprocating of 2 / 3 / 4 / 5 stages

- Direct coupling

- Electric motor or gas driven engine

- Power: 55 / 132 kW (75 / 175 HP)

- Air cooled

- Last compression stage condensers

| IODM 70 | 2-40 | 2-40M | 3-12 | 3-19 | 4 | 4R | 5-4R |

|---|---|---|---|---|---|---|---|

Type | Horizontal Reciprocating |

||||||

Number of stages | 2 | 2 | 3 | 3 | 4 | 4 | 5 |

Max. suction pressure | 60 Bar (870 PSI) 60 Bar (870 PSI) | 13 bar (189 PSI) | 19 bar (276 PSI) | 8bar (116PSI) | 4.4bar (64PSI) | 1 bar (14.5 PSI) | |

Min. suction pressure | 28 bar (406 PSI) 28 bar (406 PSI) | 7bar (102PSI) | 12 bar (174 PSI) | 4bar (58PSI) | 1.5bar (22PSI) | 0.02bar (0.29PSI) | |

Discharge pressure | 250-300 bar (3625-4350 PSI) | ||||||

Stroke (mm) | 70 | ||||||

Main motor power | 55/75/90kW (100/125HP) | 110/132kw(150/175HP) |

|||||

Air-cooler power | 2.2kw x 2 | 3kw x 2 | |||||

Voltage - Frequency | 380 / 440 vac – 50 / 60 hz | ||||||

Speed (RPM) | 1.480 / 1.780 | ||||||

| IODM 70 | 2 / 3 / 4 without enclosure | 2 / 3 / 4 with enclosure | 5 with enclosure | 5 with enclosure | 5 without enclosure with gas engine |

|---|---|---|---|---|---|

Height | 1,800mm / 5'11" | 1850mm / 6'1" | 2500mm / 8'2" | 3,100mm / 10'12 | 2100mm / 6' 10” |

Width | 1950mm / 6'4" | 3040mm / 9'11" | 2,800mm / 9' 2” | 3,600mm / 12' 3” | 1960mm / 6' 3” |

Lenght | 1940mm / 6'4" | 2,130mm / 6'11" | 1,960mm / 6' 3” | 1,960mm / 6' 3” | 4300mm / 14' 7” |

Weight | approx. 2,250-3,600kg | approx. 2,640-3,360kg | approx. 4,600-6,200kg | approx. 6,500kg | 7,800kg |

Designed for outdoor installation, reducing the noise level. Enclosure has 4 doors for easier maintenance and it is designed for any compressor system of the IODM 70 line.

Technical features

- Noise attenuation up to 68 ± 2 dB(A)

- Built in stainless steel

- Internal insulation: fireproof and soundproof material

- Connections centralized to make the connections tasks easier

- External thermo-acoustic viewer

OPTIONALS

- Corrosive environment treatment

- Explosion proof lightning

- Flame detector

- Fire fighting system